WHO WE ARE MAY NOT BE WHAT YOU THINK

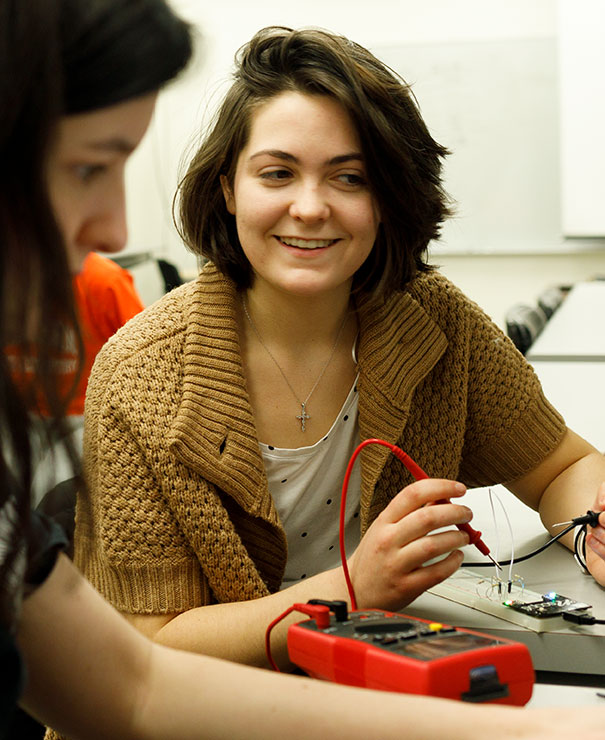

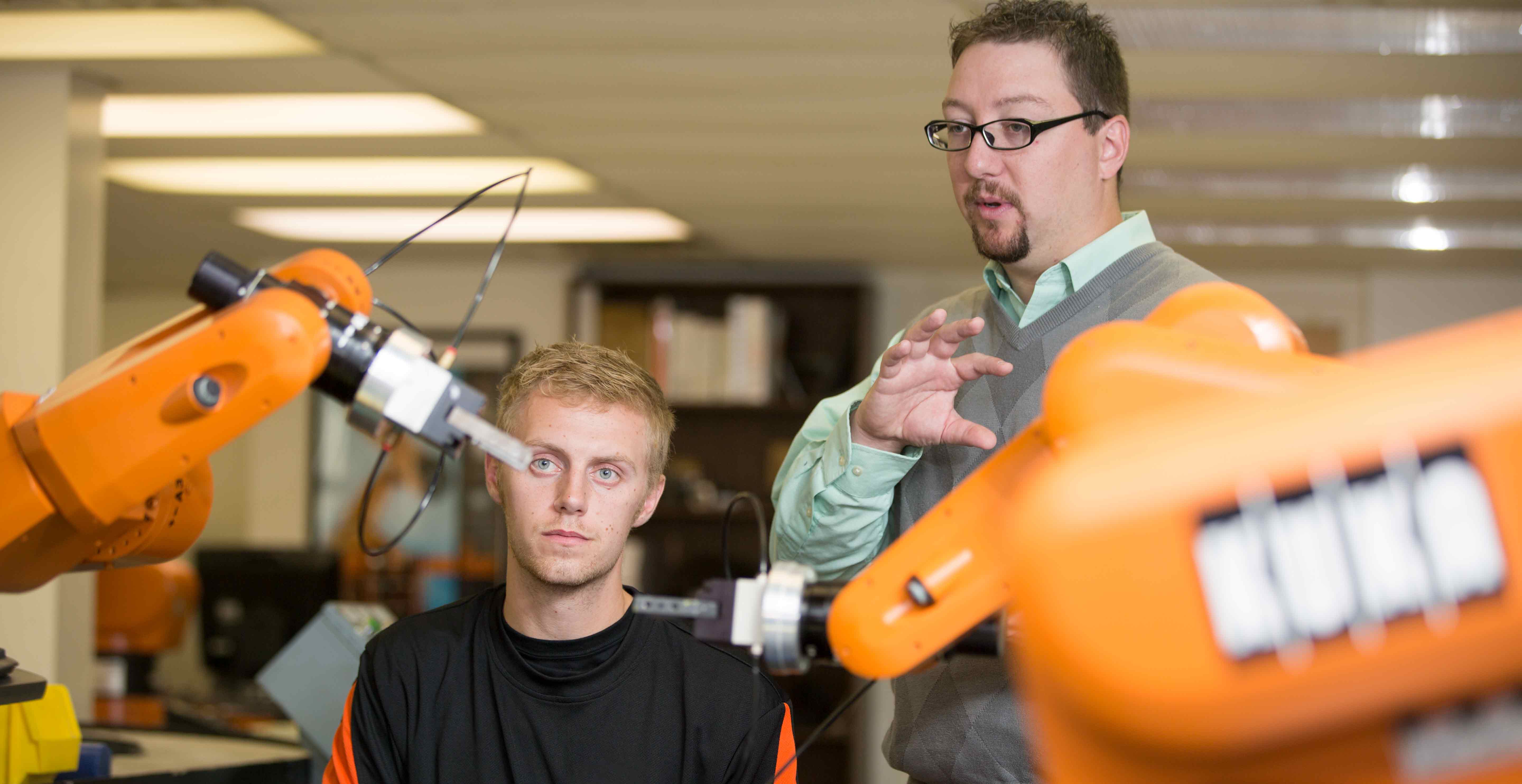

As a manufacturing technology major, you can choose to concentrate your studies on robotics or management. Both concentrations includes courses in robotics, manufacturing, computers, science and math. Our program also emphasizes hands-on learning. You’ll spend a lot of time designing, experimenting and fabricating in our labs. And you’ll tackle projects for real clients. These experiences will teach you how to work on teams, communicate effectively, problem-solve and think critically. With these skills under your belt, you’ll be in demand in the workforce.

Large institutions just can’t provide the individualized attention and opportunity you’ll find here. Our manufacturing technology students build robots and design software solutions. They assist professors with research, participate in national competitions and can co-op at leading manufacturing companies. They star on our sports teams and lead student organizations.

Here, you won’t get lost in the crowd. You’ll be part of close-knit family. You’ll enjoy small class sizes and amazing friendships with your classmates. Our dedicated professors will get to know you. They will support you in your coursework, lab work, co-ops or internships, and career preparations. They will become personally invested in your success and open doors for you.

Upon graduation, you’ll be armed with the technical knowledge and skills to carve out a terrific career!